+86 15633683072

Many manufacturers believe that once a robotic arm is installed, an automated assembly line is essentially complete. In reality, this assumption is one of the most common reasons automation projects underperform. A robotic arm assembly line is not a product—it is a system. And the difference between the two is exactly where most efficiency is lost or gained.

A single assembly line robot arm can perform repeatable motions with impressive precision. But when placed into real production, precision alone does not guarantee throughput, stability, or long-term reliability.

A true robotic arm assembly line includes:

Process sequencing and takt time balance

Tooling and fixture logic aligned with product tolerance

Communication between robots, conveyors, sensors, and PLCs

Error recovery paths, not just “ideal cycle time”

This is why factories that buy robots without system-level planning often discover that their line runs slower than manual assembly after three months of operation.

From an engineering perspective, the robotic arm is rarely the bottleneck. The problem lies in how it is integrated.

In many failed projects, we see:

Robot idle time caused by upstream fixture delays

Over-optimized robot motion with under-designed material flow

Vision systems added too late to fix mechanical problems

A 4 DOF robotic arm assembly chosen for cost reasons, but forced into tasks requiring higher orientation freedom

Without proper system design, even the most advanced assembly robot arm becomes a waiting machine.

Most performance limitations are locked in during the design phase, not during commissioning. This is where experienced industrial robotic system integrators make a measurable difference.

Key decisions that affect long-term output include:

How many stations actually need robots, not how many robots can fit

Whether a 4 DOF robotic arm assembly is suitable for the full product mix

How future variants will impact robot reach and tool access

How welding, assembly, and inspection processes interact within one robotic arm assembly line

Choosing the wrong structure forces manufacturers to compensate with software patches, longer cycle times, or manual rework.

Manufacturers often spend months comparing robot brands, while spending days selecting industrial robotic system integrators. This is backwards.

The same assembly line robot arm can deliver:

20% higher throughput in a balanced line

Or 30% downtime in a poorly integrated one

The robot executes commands. The system determines whether those commands make sense.

Experienced industrial robotic system integrators design robotic arm assembly lines around:

Real production takt, not catalog cycle times

Tool wear, heat distortion, and weld deformation

Maintenance access and operator interaction

Expansion space for future stations

This is the difference between “automation installed” and “automation working”.

A 4 DOF robotic arm assembly can be extremely efficient for planar assembly, repetitive welding paths, or fixed-orientation parts. But forcing it into multi-angle assemblies or mixed-product lines creates hidden costs.

In a properly designed robotic arm assembly line, DOF selection is driven by:

Product geometry evolution over time

Fixture reusability

Tool change strategy

Line flexibility, not just current drawings

System-level thinking prevents expensive redesigns two years later.

A robotic arm supplier delivers hardware. Industrial robotic system integrators deliver production capability.

Their value shows up in:

Stable takt time under real shop-floor conditions

Lines that recover automatically from minor faults

Robots that cooperate instead of waiting for each other

Assembly robot arm programs that remain readable after years of changes

This is why manufacturers scaling globally rely on integrators, not just equipment vendors.

We are not a robot trader. We are an automation system builder.

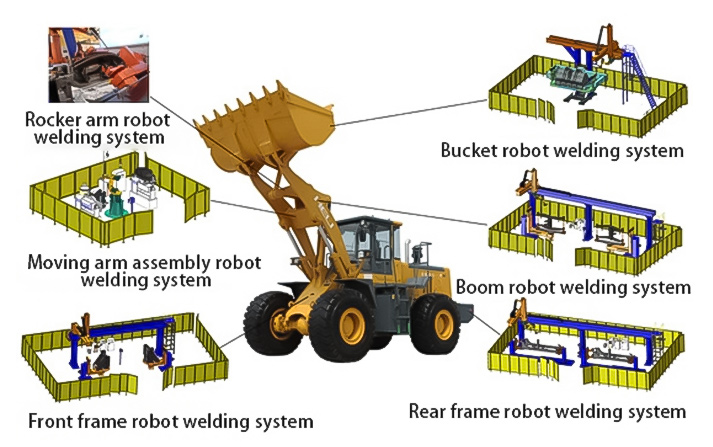

Founded in 1994, our company has focused on designing and delivering robotic arm assembly lines, automated welding robot workstations, and integrated assembly welding lines for manufacturing enterprises worldwide.

What we actually do on the ground:

Design robotic arm assembly lines based on real takt studies

Integrate welding, assembly, and material handling into one system

Deploy engineers on-site for installation, commissioning, and optimization

Build lines that can be expanded without tearing everything down

Our engineers don’t stop at startup. We stay until the line runs at its intended capacity—and keeps running.

For manufacturers looking beyond buying a robot and toward building a reliable robotic arm assembly line, choosing the right system integrator is the real first step.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com